Bathurst Coal mine CAT 988H with LOADRITE L2180 wifi data feed

Located in the Buller Coalfield on the West Coast, Stockton is the largest opencast mine in New Zealand.

The mine delivers high-quality steelmaking coal for export and has another 12 years’ reserves.

Stockton coal is bituminous and ash levels are typically low by world standards. It’s highly sought after by steel makers because of its low ash and low phosphorus content. And it swells strongly on heating making – an essential attribute for the production of quality coke.

|  |

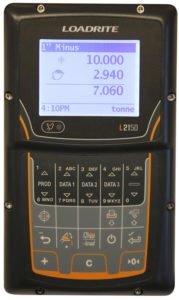

LOADRITE were commissioned to install several Loadrite L2180 wheel loader scales with wireless wifi data communication links to the main operational office for load performance management.

Load efficiency of the CAT 988H loaders which perform ROM COal load, haul and dump into a ground hopper is a critical operation requiring speed and accuracy.

Maximum working load of the machines is strictly monitored and until now this was not possible, the LOADRITE L2180 scale has been configured to only accept loaded within a specific weight tolerance, thus if the ROM material is heavy with rock the loader will not be overloaded as the operator will be instructed to reduce the load prior to cartage.

Office reports on total tonnage per shift per loader are reported on, along with average load weights and quantity of over or under target loads.

|  |

The mine is located high on the plateau with all open cast mining activity and washing activity carried out on the exposed West Coast mountaun top. All coal is carried down the mountain to stockpile and loadout operations by aerial cable way.

|  |

Loadrite accuracy and reliability is designed into the product and installation, configuration and system set up is designed to this tough all weather environment.

For more information, please call LOADRITE on 0800493444 and speak to one of the team.